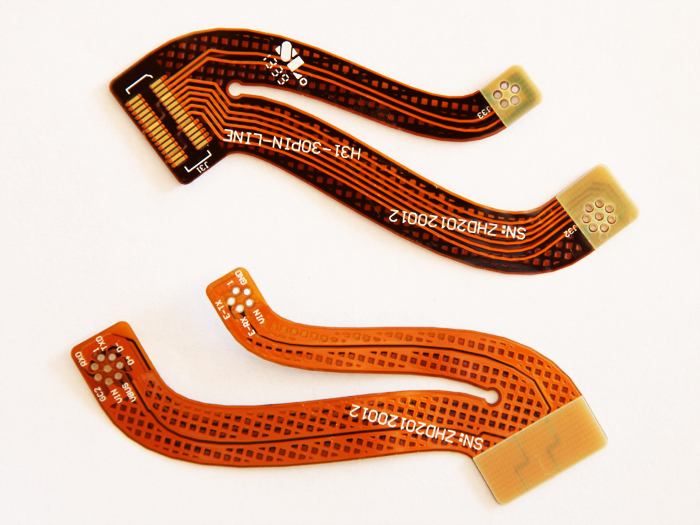

Flexible Circuit Board for Smart Watch

- Packaging:

- Vaccum Package

- Productivity:

- 10000

- Brand:

- JHY PCB

- Transportation:

- Ocean,Air

- Place of Origin:

- China

- Certificate:

- ISO9001

Product Description

With the emergence of wearable electronic devices, smart Watches, smart bracelets, smart glasses, smart gloves, smart Rings, health monitoring wristbands and so on will become a mainstream trend.

With the in-depth study of flexible electronic materials, the emergence of many flexible materials has brought new experiences for wearable electronic devices. Intelligent wearing equipment has promoted the development of Flexible Printed Circuit and Flexible Circuit Board for Smart Watch market to a certain extent.

Wearable equipment, which integrates all kinds of advanced electronic technologies, will be an important driving force for FPC flexible circuit boards and even the electronic industry in the coming years. It is expected to dominate the consumer electronics market in the future with great explosive force. Flexible Printed Circuits are flexible, lightweight and thin without reinforcing materials. Flexible Print Circuits reduces the number of electronic packaging and interconnection points, reduces the probability of electronic failure, and has strong stability, so it is very suitable for wearable equipment.

Flexible printed circuit board is a highly reliable and excellent flexible printed circuit board based on polyimide or polyester film. Flexible printed circuit board or FPC is characterized by high density, light weight, thin thickness, free bending, folding and winding, and can move and expand freely in three-dimensional space.

With good heat dissipation performance, FPC can be used to reduce the volume. It can achieve lightweight, miniaturization and thinning, so as to achieve the integration of component devices and wire connections.

FPC flexible circuit board is the basis of wearable electronic equipment. It covers organic electronics, plastic electronics, bioelectronics, nanoelectronics, printing electronics, and other fields. Its products include RFID, flexible display, OLED display and lighting, flexible sensor, flexible photovoltaics, flexible logic and memory devices, flexible batteries, wearable devices, electronic skin, etc. This includes, in particular, the need for as transparent medical equipment as possible, and the versatility of flexible and transparent circuits is sufficient for various electronic products.

With the continuous high-tech of intelligent wearing equipment, what aspects should flexible circuit boards continue to innovate in the future?

1. Thickness. The thickness of the flexible circuit board must be more flexible and thinner.

2. Bending resistance. Flexible circuit boards are inherent in flexibility, the flexibility of FPC must be stronger in the future, must exceed 10,000 times, of course, this requires better substrates;

3. Price. At present, the price of a flexible circuit board is much higher than that of PCB. If the price of FPC comes down, the market will be much broader.

4. Technological level. In order to meet various requirements, the process of flexible circuit board must be upgraded, and the minimum aperture and line width/line distance must meet higher requirements.

After a long period of technical accumulation, Jinghongyi PCB has successfully produced a large number of FPC flexible circuit boards for wearable devices.

Excellent technological ability, to meet the requirements of consumer electronic customers'flexible board production process ability, to meet the requirements of consumer electronic customers' flexible PCB board production:

- Minimum linewidth/spacing:0.05mm(1/3oz)/0.045mm(1/4oz)

- Minimum through-hole pad:0.3mm

- Coverage face-to-face tolerance:0.2mm

- Profile tolerance:0.05mm

- Max layers:8 Layers

- Pitch tolerance:+/-0.05mm

- Minimum Laser Control:0.1mm

At present, we are the main supplier of flexible circuit boards for smart wearing equipment. In addition, we also produce flexible circuit boards for 5G base stations, high-frequency PCB, high-speed PCB, radio frequency PCB, high-precision PCBs and Flexible Circuit Board Assembly services.

Prototype Flexible PCB Fanufacturer

Flexible PCB Manufacturing Capability

Learn more about JHY PCB by exploring the manufacturing capability of Flexible PCB below. We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film | |

| Silkscreen Color | White, Black, Yellow | |

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

PCB Shipment

JHY PCB offers flexible shipping methods for our customers, you may choose from one of the methods below.

Shipping Process

After production and testing, your PCB orders will be sent to our shipping department. As the quick turn PCB manufacturer, JHY PCB shipping department will ship your PCB quickly without any pending.

JHY PCB 's Packing Way

- Use one professional PCB vacuum bag, with desiccant inside. Vacuum compressed totally.

- Paste label and RoHs mark. Use second vacuum bag to protect boards again, vacuum compressed, make sure no exception.

- Microsection report and Tin testing board are put together with PCB in cartons.COC (Certificate of Conformity) will be sent to customer by email in PDF.

- Several layers of thick EPE(Expand aple poly ephylene) are filled fully in gaps between PCBs and cartons. Thickness of 1 layer EPE is 10mm.

- Neutral Packing is adopted if no special requirements. Strong and thick cartons(Thickness:10mm,7 layers). Different sizes of cartons are designed to meet demand of different PCB size. All package are within weight limit of cartons. For mass production order, no exceed 21kg per carton normally.

- All cartons sealed with strong adhesive tape should be sealed twice so as to make them more durable.

- Solid PP/PET strapping is used outside of cartons.

- Shipping mark, fragile mark and postcode label are all pasted clearly.

How to ship your PCB?

- Firstly, JHY PCB shipping department will print order address and invoice.

- Secondly, JHY PCB will set the shipment information on the Logistics company website.

- Thirdly, the Logistics company staff will collect the package from JHY PCB and ship it to you.

With the purpose of better customer service and meeting the customer demand, JHY PCB provides following shipping methods.

JHY PCB is experienced in exporting. For PCB Prototype and small-medium volume PCB order, we have stable and long-term good relationship with forwarder, such as international express company DHL, FedEx, TNT, UPS. For mass production order, we have famous and reliable shipping company for support.

FAQ

Q1: What is your minimum order quantity?

A: Our MOQ is 1 PCS.

Q2: Do you accept PCB design with different boards on one panel?

A: Of course, we can do different boards on the same panel.

Q3. Are my Gerber Files safe?

A: We protect the intellectual property for customers in the whole process. All documents from customers are never shared with any third parties.

Q4: What is needed for quotation?

A: Quantity, PCB Gerber file, Technical requirements(material, board thickness, surface finish, copper thickness,solder mask color, silkscreen color, ...)

Q5. How to quote shipping cost?

A: The shipping cost is determined by the shipment way(forwarder name, delivery days), destination, weight&dimension of packages. If you use your own forwarder, please inform us.

Product Categories : Flexible PCB